Royal Enfield Bullet 500 EFI (UCE) Maintenance Schedule and Service Intervals

This is the maintenance schedule and service intervals for the Royal Enfield Bullet 500 EFI, the latest version of Royal Enfield’s classic cruiser/standard that is partly responsible for making the company what it is today.

The Royal Enfield Bullet 500 was first made in 1932, though of course it has evolved since then.

The most recent engine was the “Unit Construction Engine” built for the 2009 model year, which from 2017 onward gained fuel injection, for the Bullet 500 EFI, to help conform to BSIV standards

Powering the Bullet 500 EFI is a fuel-injected 499cc single that makes 20 kW (27 hp). Since the late 2010s the Bullet has had ABS as standard.

In 2020, the Bullet 500 EFI was retired from production in favour of the new 650 twins, including the Interceptor 650.

This site has links for things like oil and spark plugs from which we earn a commission (which unfortunately nobody can save, not even us). If you appreciate this work, then please use those links. Thanks!

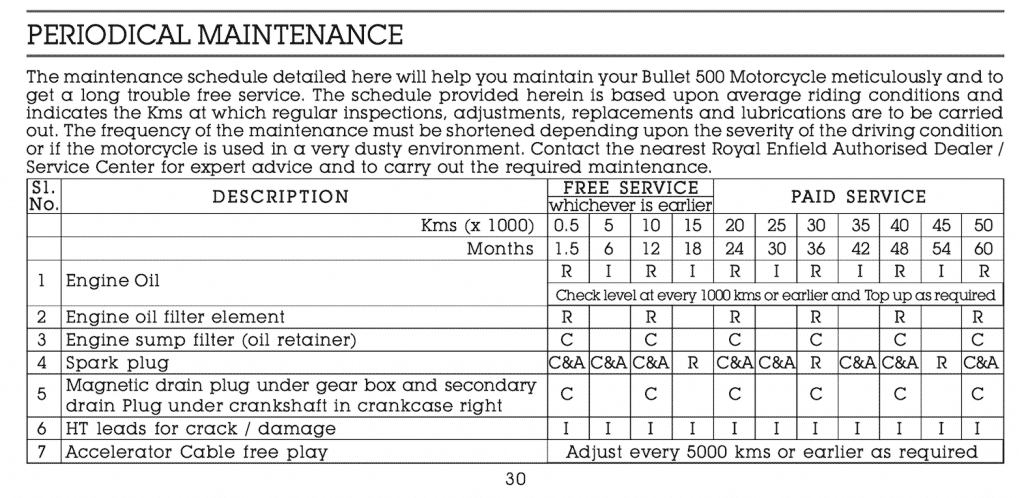

Maintenance schedule for the Royal Enfield Bullet 500 EFI

Like a few other Royal Enfields, the Bullet 500 EFI has free service in a few markets (up to 18 months), and quite a large warranty period (up to 3 years).

Beyond that, the maintenance schedule is below.

The below maintenance schedule comes straight from the manual for the Royal Enfield Bullet 500 EFI. You can do a lot of it with the on-board tool-kit, if you’re game…

Notes:

- Beyond 50,000 km, keep doing your own service after that period in the same pattern shown.

- If you ride in unusually wet, muddy, or dusty conditions, then check, adjust, and lubricate everything more frequently.

Legend

- I = Inspect (Clean, Adjust, Lubricate, or Replace as necessary)

- A = Adjust

- C = Clean

- L = Lubricate

- R = Replace

- I/A/R = Inspect/Adjust/Replace if necessary.

| Kms (x 1000) | 0.5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Months | Notes | 1.5 | 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 |

| Engine Oil (#) | Check level at every 1000 Kms or earlier as required | R | I | R | I | R | I | R | I | R | I | R |

| Engine Oil Filter Element (#) | R | R | R | R | R | R | ||||||

| Inlet / Exhaust valve clearance (**) | I&A | I&A | I&A | I&A | I&A | I&A | I&A | I&A | I&A | I&A | I&A | |

| Spark plug | C&A | C&A | C&A | R | C&A | C&A | R | C&A | C&A | R | C&A | |

| Magnetic drain plug under gear box and secondary drain plug under crankshaft in crankcase right | C | C | C | C | C | C | ||||||

| HT leads for crack/ damage | I | I | I | I | I | I | I | I | I | I | I | |

| Accelerator cable free play | Adjust every 5000 km or earlier as required | |||||||||||

| Rubber Hose, air filter to throttle body | I | I | I | I | I | I | I | I | R | I | I | |

| Rubber hose, inlet manifold/ adaptor | I | I | I | I | I | I | I | I | R | I | I | |

| Evaporative emission equipment rubber hoses | I | I | I | I | I | I | I | I | R | I | I | |

| Air filter paper element | Clean/ replace more frequently if used in dusty conditions | C | C | R | C | R | C | R | C | R | C | R |

| Clutch Cable/ lever free play | Adjust every 1000 Kms or earlier as required | |||||||||||

| PAV pipes & hose clip | I | I | I | I | I | I | I | I | R | I | I | |

| Rear brake pedal pivot | L | L | L | L | L | L | L | L | L | L | L | |

| Battery terminals (apply petroleum jelly) | C | C | C | C | C | C | C | C | C | C | C | |

| Earth wire eyelet contact | I | I | I | I | I | I | I | I | I | I | I | |

| Front fork oil leak | I | I | I | I | R | I | I | I | R | I | I | |

| Rear wheel drive chain | Clean, lubricate every 1000 km; adjust every 5000 km or earlier as required | I&A | ||||||||||

| Spoke tightness/ wheel rim run out front and rear | I | I | I | I | I | I | I | I | I | I | I | |

| Steering ball races play | Inspect & if required lubricate every 5000 km or earlier as required. Replace if necessary | I&A | ||||||||||

| Swing arm pivot bush and spacer | Inspect & if required lubricate every 5000 km or earlier as required. Replace if necessary | I | ||||||||||

| Rear wheel cush rubbers | I | I | I | I | R | I | I | I | R | I | I | |

| Tyre wear pattern front and rear | I | I | I | I | I | I | I | I | I | I | I | |

| Disc brake fluid level – front and rear | I | I | I | I | R | I | I | I | R | I | I | |

| Pivot – side stand, centre stand, pillion foot rest | L | L | L | L | L | L | L | L | L | L | L | |

| Throttle body | Throttle body cleaner every 5000 km/6 months or earlier as required | |||||||||||

| Fuel hose & clip | I | I | I | I | I | I | I | I | R | I | I | |

| Front and rear brake hose and banjo bolt | I | I | I | I | I | I | I | I | I | I | I | |

| Hand levers & kick starter lever (where fitted) pivot | Lubricate every 1000 kms or earlier as required | |||||||||||

| Clutch cable | I&A | I&A | I&A | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | |

| Accelerator cable | I&A | I&A | I&A | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | I&A/R | |

| Starter motor & starter relay connections | I | I | I | I | I | I | I | I | I | I | I | |

| Rear brake pedal free play | Adjust every 1000 km or earlier as required | |||||||||||

| Brake Pads – Front & Rear | I | I | I | I | I | I | I | I | I | I | I | |

| Side stand switch operation | I | I | I | I | I | I | I | I | I | I | I |

Tyre sizes and pressures for the Royal Enfield Bullet 500 EFI

Below are the tyre sizes and pressures for the Royal Enfield Bullet 500. The Bullet 500 EFI carries tubed tyres for its spoked rims.

| Wheel | Tyre size | Tyre pressure (cold) |

|---|---|---|

| Front | 90/90-19 – 52 P | 20 psi / 1.41 bar (22 psi/1.55 bar with pillion) |

| Rear | 120/80-18 – 62P | 30 psi / 2.11 bar (32 psi/2.25 bar with pillion) |

About the Royal Enfield Bullet 500 EFI

The Royal Enfield Bullet 500 is an iconic bike in Royal Enfield’s line-up.

Together with the Bullet 350, the Bullet 500 name is synonymous with the brand. The Bullet was the first model of the then-British manufacturer, and in its original forms was used all over the world as commuter bikes and army bikes.

Since 1932 and the first Bullet motorcycles, Royal Enfield has gone through a lot, as has the world. Royal Enfield was re-invigorated in the late 90s and early 2000s, and since 2009 the Bullet 500 has had a more advanced single-body engine, which since 2017 has had fuel injection. From 2017-2020, to help it conform with European emissions standards, it even came with ABS!

At its core, the Royal Enfield Bullet 500 EFI is based around a 499 cc single that’s fairly square. It’s fuel-injected, air cooled, and has overhead valves. It makes not a lot of power (20 kW / 27 hp), but like many low-powered single-cylinder motorcycles, the Royal Enfield Bullet 500 EFI is more about nostalgia and cost-efficiency than it is about having a high-powered cruiser.

In India especially, the Bullet 500 EFI is a motorcycle that’s the “goal” motorcycle of many Indian young men. Or at least it used to be maybe two decades ago.

The rise of incomes and availability of higher-quality products has many domestic buyers leaning towards either higher-end Royal Enfield motorcycles (like the 650 twins), or just other brands altogether — you can find many high-power sport bikes in India these days.

So the Royal Enfield Bullet 500 EFI met its end in 2020, when it was replaced in the international and domestic line-ups by the 650 twins.

But the Bullet 500 EFI still represents an age of “simplicity” for Royal Enfield. You can find many of them in the used market (and many more of the earlier carburettor-fed model) and buy them used, and then assuming normal maintenance, usually sell them for what you paid for them.

Unfortunately, the Bullet 500 EFI is no longer in production.

The Bullet 350 EFI is still manufactured though, and people like it as a classic commuter. However, the Meteor 350 means that even the Bullet 350’s days are numbered

Manual for the Royal Enfield Bullet 500 EFI

The above maintenance schedule came straight from the manual for the Royal Enfield Bullet 500 EFI (latest version, 2020).

A screenshot of this maintenance schedule is below. More is in the manual (or above).

Royal Enfield provides all their manuals online and they’re full of diagrams and photos of how to do the maintenance. You can download them here.